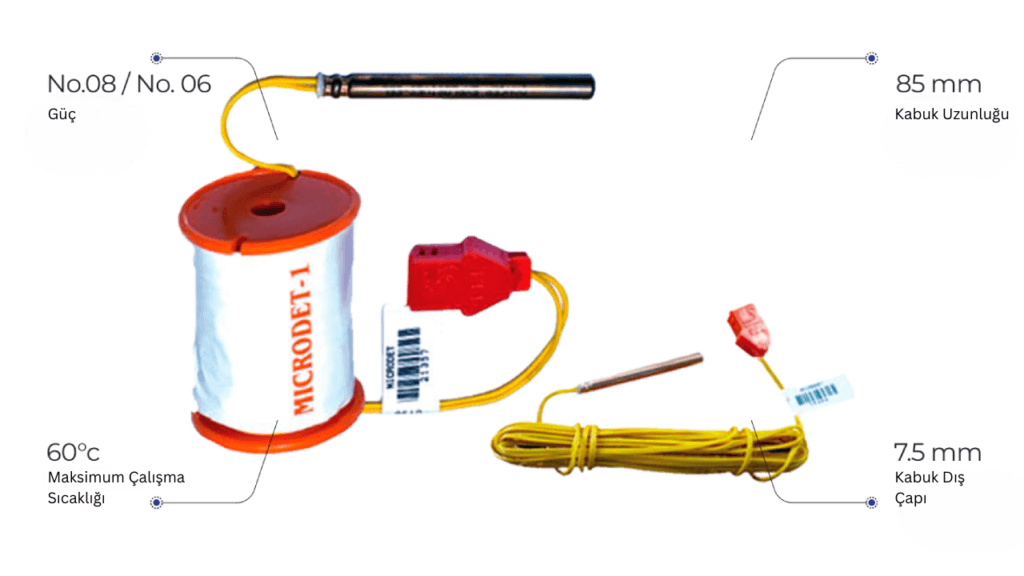

Product Description

Programmable Electronic Detonator The Electronic Ignition System offers high accuracy, reliability, and programmability.Product Technical Specifications:

| Parameter | Value |

|---|---|

| Shell Material | Aluminum / Copper |

| Power | No.08 / No.06 |

| Shell Length | 85 mm |

| Shell Outer Diameter | 7.5 mm |

| Delay Range | 0 ms – 8000 ms |

| Maximum Operating Temperature | 60 °C |

| Water Resistance | Excellent |

| Connection Cable Material | Copper Coated Steel / Copper |

| Maximum Connection Cable Length | 60 Meters |

| Main Conductor Wire Material (Resistance) | Copper, Two-Colored (0.07 Ω/m) |

| Maximum Circuit Resistance | 100 Ohms |

| Delay Accuracy | Up to 500 ms: ±1 ms, Over 500 ms: ±0.2% |